| 1 |

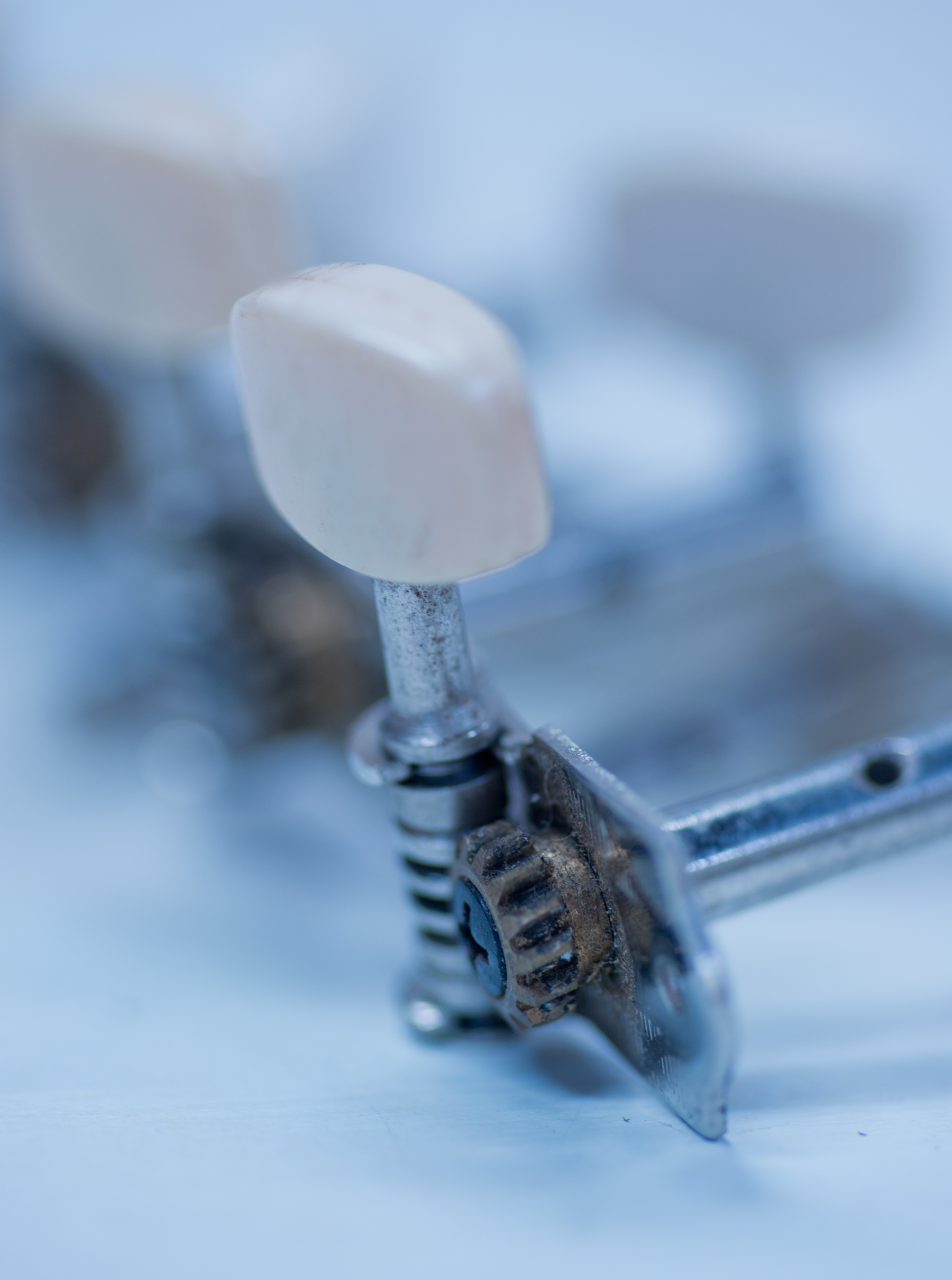

It is best not to increase the weight of the machineheads/ tuner. |

| 2 |

Do not use cheap hardware, they tend to slip out of tune. Cheap hardware, typically the string holes are not chamfered causing the stings to snap. Basically they are false economy. |

| 3 |

Check the ratio is correct, some machineheads are very coarse and other are fine, meaning you either turn a little or a lot to adjust the tension. |

| 4 |

For many obvious reasons, mainly consistency and looks it's best to replace all machineheads and not just one or two at a time. If the tuners are from a quality instrument, replace them with what they came with, it will cost a little more, but consider the options, drilling holes into the headstock and the risk of suffering all the above issues. |

| 5 |

Finally the tuners may not be the issue, if your instrument is going out of tune, check to see if the nut and saddle are correctly set up. |

| 6 |

String slip is the most common reason instruments go out of tune. It might be your technique of stringing your instrument that needs some revision. |