Bindings, aside from the aesthetic appeal, offer the instrument protection in a couple of ways. Bindings reduce damage to the edges of the instruments from impact. They protect the timbers from moisture especially the end grains as they encapsulate the joins of the various components such as sound board and the back and sides. Bindings offer a degree of strength to the edges of the instrument, as they are a laminate, instruments that have no bindings are susceptible to cracking in certain areas as the end grains face the edge of the instrument.

Why and how does any of this matter : When an instrument ages it has two roads to travel : one it improves. Well made instruments age with redeeming well, poorly made instruments deteriorate and often loose any qualities they might of had.

Here we can see I'm hand fitting a series of Paua inlays, the chisel is used to true the cavity before fitting the inlays. You will notice the Paua is currently covered by paper patterns.

Here I'm correcting the binding groove, this is a process I do after machining, because the back is not a flat surface there is a complexity of shapes and angles that require fine tuning. Bindings that are well set don't suffer from gaps and filler. If you are looking at instruments always look at the bindings and see if there has been any poor workmanship. If the instrument isn't well bound and the inlay work is messy, then the Luthier hasn't worked to a very high tolerance and it is reasonable to say the instrument is not well made.

Here I am planing the bindings and purfling, this is a finicky process. The trick is to only plane the binding and inlay, great effort is made not to mar the back or the soundboard. Wooden bindings require considerably more work as they require pre bending before fitting. The reason manufactures use plastic, it is quicker to fit and doesn't suffer from staining blemishing or discolor from wood fillers and or sanding dust.

Next I move onto a scrapper rather than sanding, because the sanding dust will discolor the light colored bindings, the purpose here is to level the bindings and back surface.

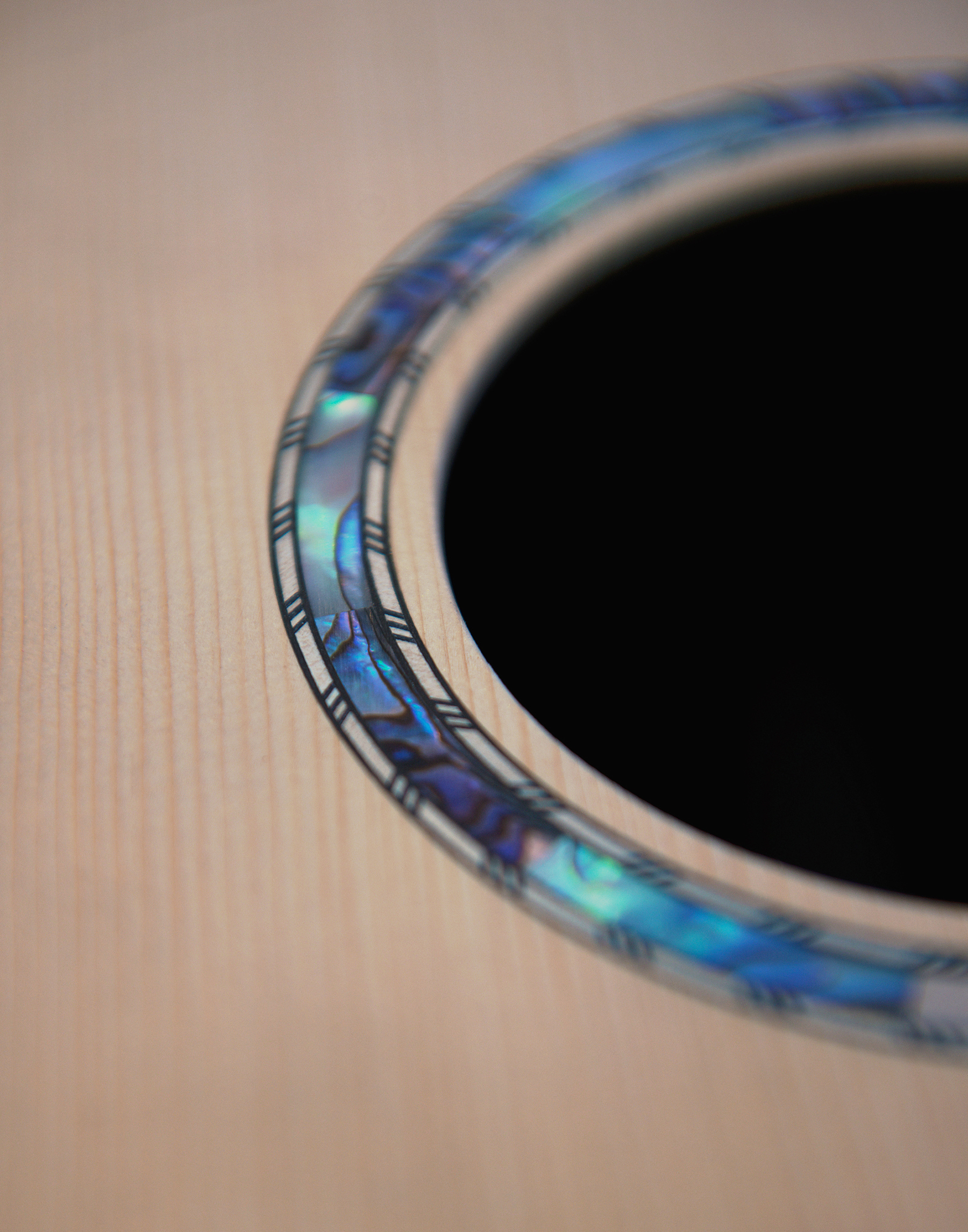

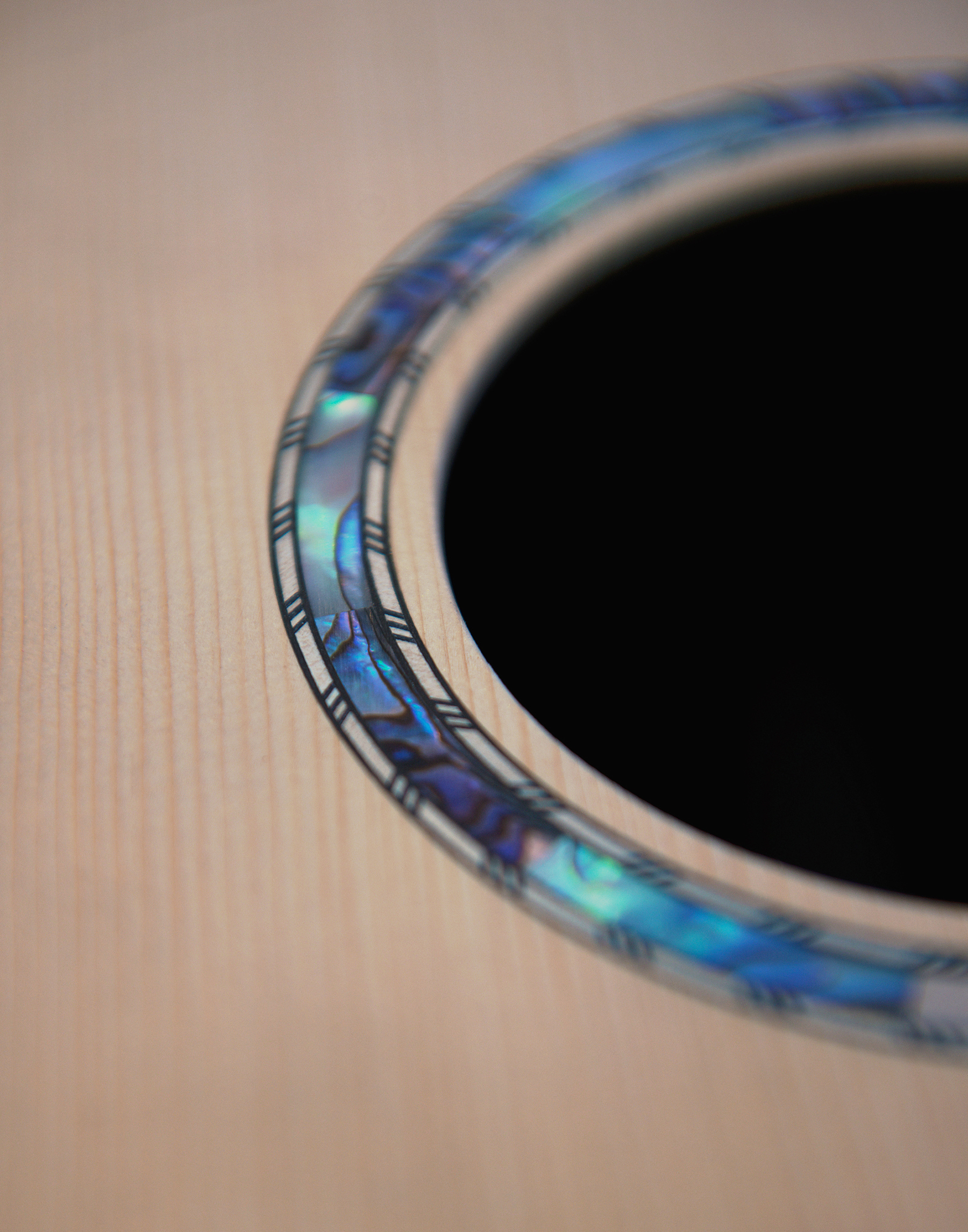

Paua inlay around the sound hole. Does the inlay offer any qualities to the sound of the instrument. As I have mentioned before I believe every thing offers something, its a matter of how much, I suspect the inlay around the sound hole would be a minor player in the overall tone and sound. I am not aware of any studies on this point. A practical purpose of the rosette is to prevent cracking around the sound hole.

Return to the top of the page